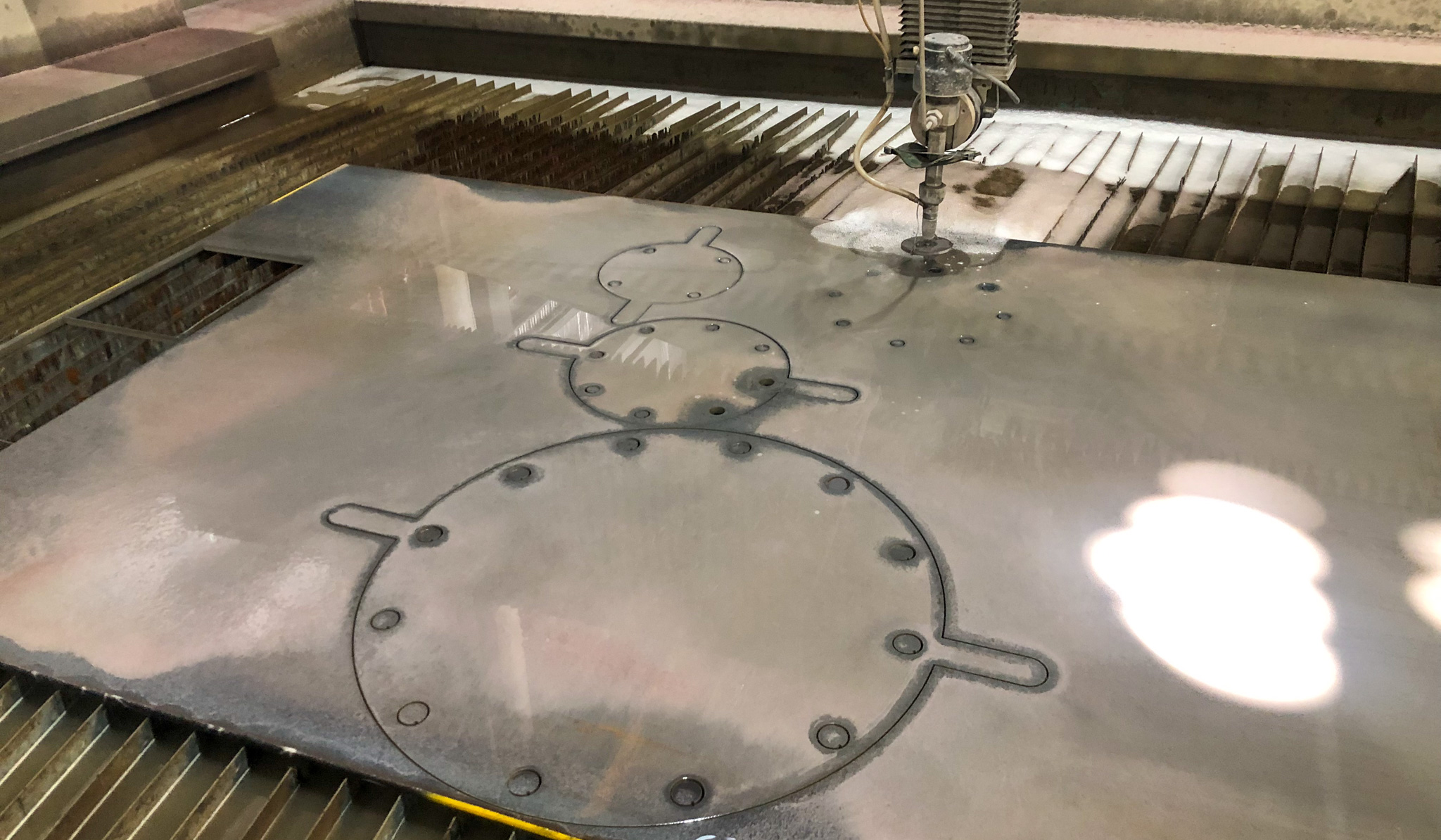

CNC Watercutting

We can produce a wide range of custom design profiles using our Techjet 4100-X3. The waterjet can cut almost any material using maximum cutting speeds and can cut a total size of 2100mm x 4100mm and up to 200mm thick.

Manufacturer

TECHJET

Model

4100-X3

Cutting Area

2100 x 4100mm

Maximum Material Thickness

200mm

ADVANTAGES

This innovative system has many application in construction and building design and there are many reasons why waterjet cutting is preferable other other cutting methods.

- No Heat – There is no heat generated. This is especially useful for cutting tool steel and other metals where excessive heat may change the properties of the material.

- Clean – unlike machining or grinding, waterjet cutting doe not produce any dust or particles that are harmful if inhaled.

- Less Wastage – The kerf width in waterjet cutting is very small, and very little material is wasted.

- Efficiency – Waterjet cutting can be easily used to produce prototype parts very efficiently. An operator can program the dimensions of the part into the control station and the waterjet will cut the part out exactly as programmed. This is much faster and cheaper than drawing detailed prints of a part and then having a machinist cut the part out.

- Automation – Waterjet cutting can be easily automated for production use.

Projects

Constitution Place

Constitution Place is a landmark structure and premium business address located on the corner of...

National Museum of Australia

We were engaged on this project based on our skills and experience working in sensitive...